ドライアイス ブラストは、製品の品質を向上させ、スクラップ、洗浄コスト、ダウンタイムを削減する経済的な洗浄技術です。また、金型や工具の摩耗も軽減されます。ドライアイス ブラストは、射出成形、押出成形またはブロー成形、その他の成形品のバリ取りに適しています。

プラスチック成形業界におけるドライアイスブラストの主な用途

ドライアイス ブラストは、プラスチック産業における洗浄用途のさまざまな要件を完全に満たします。 ドライアイス洗浄機 表面と相互作用することなく、金型の残留物や汚染物質を優しく安全に除去するように設計されています。

ドライアイスは敏感な機器には浸透せず、残留物を残しません。ドライアイス ブラストは、プラスチック製品の表面処理、研磨キットの洗浄、脱型、および成形部品のバリ取りに使用できます。

従来のプラスチック製品のバリ取り方法の欠点

プラスチック部品は熱可塑性エラストマーや熱可塑性材料からなる成形品であり、バリの多くはパーティング面に発生します。即ち、可動金型と静止金型の間、部品とのスライドのスライド、ギャップのインサート、トップバーの開口部等が溶融物内に侵入し、部品上に過剰なフレッティングバリが形成される。このバリは直角、溝、外円、内穴、交差穴、皿穴などのプラスチック部品に集中していることが多いです。

一般に、純粋に手作業によるバリ取りプロセスでは、多かれ少なかれプラスチック部品の表面に打撲傷、引っかき傷、または残留物が生じます。そして、それは企業に多大な資金と人的資源を費やすことになり、その効果は理想的ではありません。

プラスチックの特性により、大規模な機械的バリ取り手段の使用は困難です。同時に、化学的なバリ取り方法は、プラスチック部品の化学反応、損傷、腐食を引き起こす可能性があるため、プラスチック部品には推奨されていません。

プラスチック製品の大量生産では、プラスチック部品の表面の平滑性が技術仕様を満たし、製品の品質と効率が向上するように、合理的な表面処理方法が必要です。

プラスチック製品のバリ取りにドライアイス洗浄を使用する利点

製造工程において避けがたいプラスチック製品の溶液に対するドライアイス洗浄バリ取りは、仕上げ後のバリ現象の発生を避けることができ、優れた性能を発揮します。

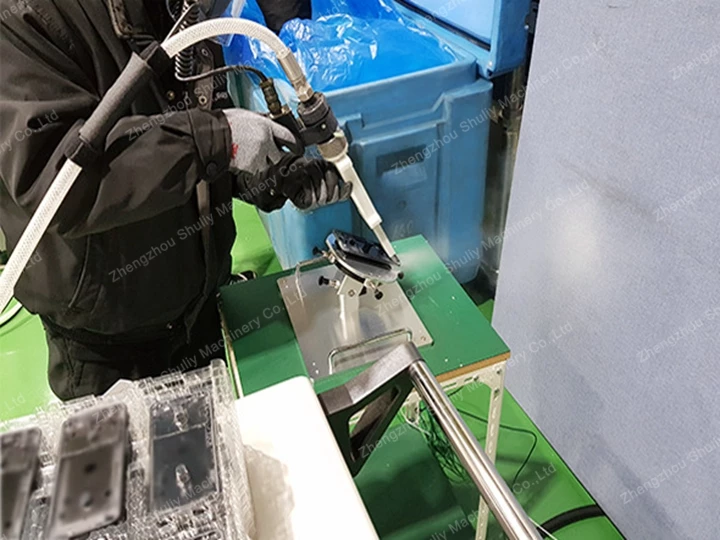

ドライアイスブラストは、 ドライアイス ペレットを高圧気流中で衝撃を加速させ、製品のプラスチック部分をバリ取りします。ドライアイスはその過程で瞬時に蒸発し、二次廃棄物を出さず、掃除が必要な汚れだけを残します。

ドライアイス洗浄バリ取りの最大の特徴は、非接触で残留物がなく、プラスチック部品の最も自然な状態でバリ取り作業を完了することができます。

ドライアイスブラストは、プラスチック部品の溝、外丸穴、内穴、十字穴、皿穴に隠れたバリを迅速かつ効率的に除去できます。また、射出成形ロボットと直接使用して、直接定点バリ取りの際に部品をピックアップすることもできます。

ドライアイス洗浄により、製品の外観や構造上の欠陥を最小限に抑えることができます。 PEEK、PBT、アセタール、ナイロン、LCP、PP、ABS、UHMWPE、ニッケルチタン合金、アクリル、フェノール、その他のフライングエッジ部品やバリ洗浄に非常に適しており、人件費を大幅に削減し、加工サイクルを短縮できます。製品の歩留まりを向上させます。